Abstract: Over the twentieth century, various types of synthetic fibers were invented, mass-produced, and widely distributed across the globe. This article analyzes the political power that was exercised to generate this innovation in musical instrument industries. Synthetics also contributed to the growth of the global garment, textile, sporting goods, and military industries, among many others. This article specifically discusses the politics behind the transition from the use of silk to nylon during the World War II and Cold War eras. Modern cultural industry’s tendency in the mid- to late twentieth century to favor synthetic and other “man-made” fibers over natural ones was importantly shaped by political-economic––and political-ecological––conflicts between the United States and Japan, especially during World War II. These conflicts prepared the ground for the rise of global capitalism’s synthetic regime.

Keywords: capitalism; critical theory; cultural industry; geopolitics; global history; materiality; political ecology

Introduction

In an interview, Spanish guitarist Andrés Segovia once told a story about nylon strings he had used since 1947.1 The interview was published in the March-April 1982 issue of DuPont Magazine, which, between 1913 and 2003, publicized the products and development of the chemical company DuPont. French-American chemist and industrialist Éleuthère Irénée du Pont established this company in July 1802 in Wilmington, Delaware. In the late 1930s, DuPont famously invented nylon, and Segovia’s guitar strings were made from the company’s nylon monofilaments. Segovia performed continuously since 1907, when he gave his first public concert. World War II, however, made it almost impossible to gain gut strings made from lamb intestines from Germany. Furthermore, during the course of his career, he experienced some technical problems with the quality of gut strings. Segovia commented in the interview:

I was irritated by the strident sound of the first string, the lack of mellowness of the second, and the frankly harsh and somber tone of the third. Tuning them was a veritable labor of Hercules, exhausting the patience of the player, and even more the listener who would finally give vent to his irritation in taunts and jests. “If you live 90 years,” one wit said to me, “you’ll have spent at least 70 of them tuning your guitar” (in “Virtuoso String Performers” 1982, 6–7).

Albert Augustine in New York City manufactured the nylon guitar strings; Segovia convinced his friend Augustine to develop the product. The transition from the use of the natural material, gut, to that of the synthetic material, nylon, notably affected the quality of the guitar string “in terms of durability, sound, ease of action, and controlled calibration” (“Virtuoso String Performers” 1982, 7).

The story of nylon classical guitar strings around the mid-twentieth century is meaningful in certain respects; it can tell more than just the material history of the classical guitar, or even that of Western musical instruments in general, including the violin, the viola, the cello, and the harp. The invention of nylon strings can be situated in a broader context where various types of industrial chemicals were invented, distributed, and used across the globe. The invention of synthetics contributed not only to the music industry, but also to the global garment, textile, and sporting goods industries, among others. During World War II, the United States mass-produced nylon for military goods. The global-historical approach to the study of nylon and other industrial chemicals helps conceptualize the rise of the synthetic regime in capitalist economies. This applies to Japanese traditional music as well. Many of the stringed musical instruments of Japanese traditional music, including the shamisen (three-stringed lute) and the koto (thirteen- or seventeen-stringed zither), used silk strings. However, since around 1960 nylon became a standard material for this tradition, as it had already emerged in Japan during the Allied Occupation period (1945–1952).

I analyze the political power that was exercised to generate this broader transition in cultural industries over the twentieth century. This article specifically discusses the politics behind the transition from the use of silk, a natural fiber or tennen sen’i, to nylon, a synthetic fiber or gōsei sen’i, during the World War II and Cold War eras. In the early twentieth century, Japan was the largest producer and exporter of silk in the world. The United States imported a huge amount of Japanese silk, having become Japan’s largest export market for silk. Nevertheless, as World War II intensified, the Unites States discontinued the import of Japanese silk and invented nylon as a silk substitute. After the war, nylon manufacturing rapidly spread across the Global North. Modern cultural industry’s tendency in the mid- to late twentieth century to favor synthetic fibers over natural ones was importantly shaped by the political-economic conflicts between the United States and Japan, especially during World War II. These conflicts prepared the ground for the rise of global capitalism’s synthetic regime. Post-World War II geopolitics also explains the growth of synthetics and related cultural industries in Japan; US policymakers during the early Cold War period were prioritizing the development of strong anti-communist allies, which facilitated Japan’s outstanding economic performance (Beckley et al. 2018).

While this study makes visible the twentieth-century capitalist ethos of artificially reproducing the natural in the dynamics and politics of global economies, it also points out that producing nylon itself has a negative impact on the planet. According to Thiemens and Trogler (1991, 932), producing nylon creates nitrous oxide in the earth’s atmosphere, which “contributes to catalytic stratospheric ozone destruction and is also a greenhouse gas component.” This environmentally problematic process took place mostly in the Global North over the twentieth century, thereby contributing, in its own way, to “the global structure of inequality” (Roberts and Parks 2009).

Man-Made Fibers in the Age of Global Industrial Chemicals

Prior to the twentieth century, there were numerous attempts by chemists and scientists in Europe to create artificial fibers. As early as 1664, English scientist Robert Hooke studied the possibility of creating an artificial silk. In 1855, Georges Audemars de Lausanne, Switzerland received a patent on an artificial fiber made from nitrocellulose. Also, in 1883 Englishman Joseph Swan obtained a patent on a nitrocellulose filament for electric lighting. Audemars and Swan both discovered some basic principles that would underlie the production of synthetic fibers (Darlington 1934, 11). French chemist Count Hilaire de Chardonnet perfected a textile fiber that would supplant silk in 1884; he has often been recognized as “the father of the rayon industry.” In that year, the production of rayon began in France, and then spread rapidly to Britain, Italy, Germany, and Switzerland. In 1910, a rayon plant that was based on the viscose process was built in the United States, and in the following year, the production of rayon started there. Around 1925, a group of North American manufacturers coined the word “rayon,” which was intended to replace the older term “artificial silk” (Darlington 1934, 14–15).

In the twentieth century, rayon was classified as “man-made fiber” (see, for example, Airov 1959; Grover and Hamby 1951; Harris 1954; Moncrieff 1963; Parsons and Stearns 1951; Sherman and Sherman 1946). As a general category of materials, man-made fibers stood for “a very significant contribution made by chemistry to progress and change in the field of textile manufacture” (Airov 1959, 5). Rayon was originally designed to imitate silk, one of the most expensive and versatile natural fibers in the modern textile industry. A clear distinction between natural and man-made fibers was being drawn; the former included cotton, silk, wool, ramie, and many others of mineral, vegetable, or animal origin, while the latter included materials invented and developed out of the industry’s chemical revolution over the twentieth century.

Furthermore, there existed two different groups of man-made fibers in the discussions of modern industrial chemicals of the twentieth century. One such group consisted of fibers made from natural polymers which are obtained in plants and animals, such as rayon and acetate. The other consisted of relatively newer fibers manufactured from synthetic (or human-made) polymers, including nylon, Dynel, Acrilan, Orlon, and Dacron, among others. Already in the 1930s, DuPont commercially introduced nylon (nylon 66) to the public. An American chemist at the company, Wallace Hume Carothers invented this synthetic material. The DuPont company advertised this new material as follows:

Though wholly fabricated from such common raw materials as coal, water and air, nylon can be fashioned into filaments as strong as steel, as fine as the spider’s web, yet more elastic than any of the common natural fibers and possessing a beautiful luster (in Furukawa 2007, 276–77).

Sherman and Sherman (1946, 11) explained that the carbon obtained from coal, the oxygen and nitrogen obtained from the air, and the hydrogen obtained from water were synthesized to make adipic acid and hexamethylene diamine. These were, then, combined under appropriate conditions to produce nylon (polyamide). “Synthetic fibers” referred only to those fibers manufactured from such synthetic polymers, and the term itself was not exactly a synonym for “man-made fibers.”

Since around the mid-twentieth century, various kinds of synthetic fibers were invented and produced across the world, but mostly in the Global North. After World War II, DuPont began to expand its influence over Europe and South America; the company established plants in such locations as Maydown, Northern Ireland and Paulínia, Brazil. Following DuPont, the Chemstrand Corp., a joint venture of Monsanto Chemical and American Viscose, entered the nylon 66 market. Experiencing substantial growth especially between the mid-1950s and the early 1970s, the synthetic-fiber-producing industry of the United States was primarily located in Virginia, Tennessee, Alabama, North Carolina, and South Carolina (Clayton 1981, 14). Outside of the United States, several chemical companies based in Canada, France, Italy, and England were producing nylon 66 already in the 1950s; these companies include Canadian Industries (Canada), Société Rhodiaceta (France), Soc. Electtrochimica del Tore (Italy), and British Nylon Spinners (England) (see Harris 1954, 46).2 Moreover, in the late 1930s Germany invented another kind of the material, which was categorized as nylon 6, and sold it under the name of Perlon L.

In East Asia, China began nylon research and production during the 1950s (see Rosato 2005, 18–19). In 1951, Tōyō Rayon, a private company based in Japan, formed a technical tie-up with DuPont, which spurred the production and spread of nylon goods in Japan during the Cold War period (see “Tōyō Reeyon to Dhu Pon de teikei” 1951). As for the global man-made fiber industry, the United States, West and East Europe, and Japan were the principal locations of manufacture (Clayton 1981, 18). This contributed, for example, to the development of the global garment industry; Susannah Handley (1999) thoroughly discusses the twentieth-century fashion revolution in North American and European contexts.

The Rise of the Synthetic: Political-Economic Conflicts Between the United States and Japan and Postwar Geopolitics

In Japan, as the Meiji Restoration of 1868 abolished the feudal system of the Tokugawa regime, the new Meiji government (1868–1912) constructed a powerful industrial sector by adopting the latest Western technology of that time. The government promoted sericulture and silk textile production as the most effective means to gain foreign currency and become a military power, which facilitated imperialism at the turn of the century (Takizawa 1979, 28). During the 1870s, the Meiji government invited foreigners from France and Italy as instructors who would teach silk techniques in state-owned silk-reeling factories. These European countries plus China were the most advanced nations in silk production. Established in 1872, the Tomioka Silk Mill in Gunma Prefecture is Japan’s first modern silk-reeling factory, which originally functioned as a training institute only for female workers.3 The government assembled hundreds of young female workers across the country at the Tomioka Silk Mill, and there they learned how to use new silk-reeling machines and silk technologies just imported from France, besides steam engines. These female workers later became instructors in local silk mills across the country. According to E. Patricia Tsurumi (1990, 32), by 1879 about 665 silk-reeling factories were in operation in Japan.

Whereas until 1880 Japan was mostly exporting silk to Europe, by the end of the nineteenth century the United States became Japan’s largest export market for silk. For instance, from 1919 to 1921, about 95 percent of exported silk went to the United States (Sangyō Gijutsu Kenkyūjo 2010, 11). By 1910, Japan already became the largest exporter and manufacturer of silk in the world, with its peak around 1930 (Table 1). In this context, various research and testing institutes, sericulture laws, and silkworm inspection rules were established for the purpose of maximizing the production of raw silk with its high quality (see Onaga 2010, 2013; Yamada 2020b).

|

Table 1. Statistics on the Export of Japanese Raw Silk, 1874–1932. |

|

|

Year |

Total Export of Raw Silk (tons) |

|

1874 |

588 |

|

1880 |

876 |

|

1890 |

1,266 |

|

1900 |

2,779 |

|

1910 |

8,908 |

|

1920 |

10,481 |

|

1930 |

28,639 |

| 1932 | 32,912 |

Source: Uchida (1994, 36).

The silk string used for traditional Japanese musical instruments was born out of Japan’s industrialization process and industrial capitalism. Today, there are only four remaining silk string manufacturers in this country. One of them is called Tobaya. Located in the city of Kyoto, Tobaya was established in 1885 as a string maker for musical instruments. The origin of Tobaya was traced back to the mid-seventeenth century, but at that time it was a textile dyeing house. In 1849, it began to make silk strings for musical instruments. Tobaya changed its industry type from textile dyeing to musical string making during the mid-to-late nineteenth century. Based on the historical information above, we can surmise that the political-economic circumstance during the early Meiji period prepared the ground for this shift.

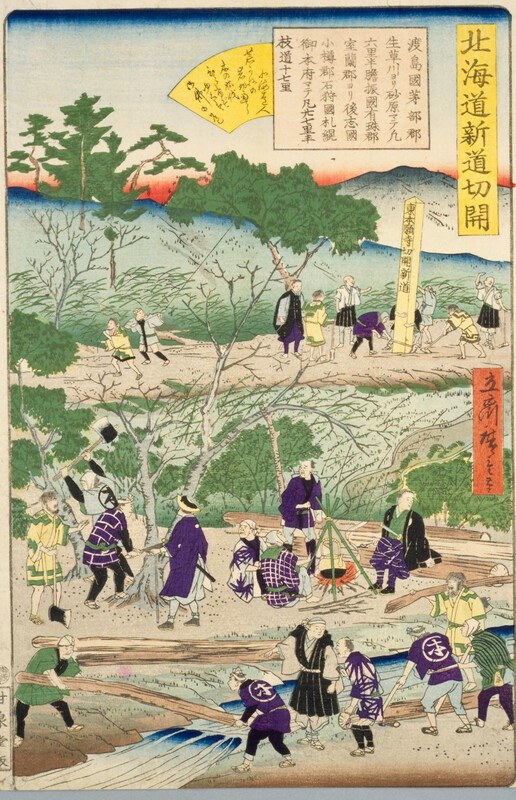

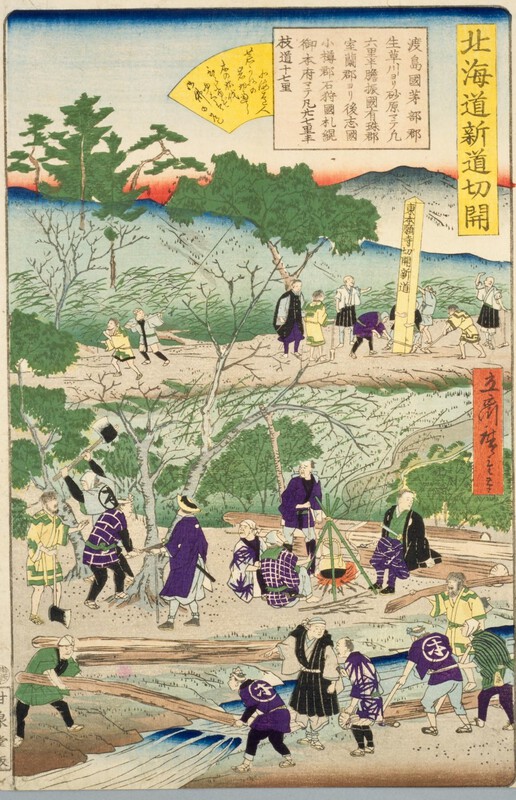

Another remaining silk string manufacturer called Marusan Hashimoto was established in 1908, during the Meiji period. The company is located in Kinomoto-chō, Shiga Prefecture, in the western part of the Japanese mainland. The company today produces approximately 400 types of musical strings; they are different in weight, thickness, and silk quality. It specifically manufactures musical strings used for the shamisen, the koto, the kokyū (three-stringed bowed fiddle), the biwa (four- or five-stringed fretted lute), the sanshin (Okinawan three-stringed lute), and so forth (Figure 1). At Marusan Hashimoto, nenshi (twisting threads) constitutes the most fundamental process of making silk strings. Multiple silk threads are twisted together, and they become a single thicker and stronger silk string. Marusan Hashimoto developed its own technique of nenshi called koma-yori (twisting silk threads with tops). In the process of koma-yori, tops that are suspended on silk threads are spun by hands, so that these silk threads get twisted together. Depending on the thickness of silk strings they are making, craftspeople change the degree of spin. The company has used this koma-yori technique since 1908.

Figure 1. Marusan Hashimoto’s silk strings used for the shamisen. Photo by the author.

Modern cultural industry extracted the vitality itself of certain nonhuman species. This development was essentially contingent on species-specific metabolism and other vital processes that were made to labor (cf. Beldo 2017; see also Yamada 2020b on the notion of “more-than-human labor”); organic bodies themselves became commodities in capitalist economies. Moreover, in the case of the sericulture industry in modern Japan, biopolitical power was exercised upon the body of silkworms to increase the total production of cocoons and silk (Yamada 2020b).4

United States Tariff Commission (1941, 159) noted that Japan was the largest producer of silk in the world, and the United States as its largest consumer obtained huge amounts of silk from Japan. In 1929, US imports of raw silk from all countries, mainly including Japan, China, Italy, and France, added up to 87 million pounds, valued at 427 million US dollars; thereafter, these imports declined in quantity in each succeeding year, except the years 1931 and 1935 (United States Tariff Commission 1941, 159). We should note here the world depression of the 1930s, which was preceded by the American stock market’s collapse in 1929, and Japanese cocoon prices fell by 55 percent in 1930 (Smethurst 1986, 95–96).5 Moreover, rayon was already available in the textile and fashion industry. The main use of the imported raw silk was in the production of woven fabrics that constituted man-carrying parachutes, balloons, and parachutes for pyrotechnic signals and flares. It was for military purposes. Silk fiber played an important role in the growth of the hosiery industry in the United States––though it was later replaced with nylon.

Around the time that Japanese forces attacked Pearl Harbor in December 1941, the United States cut off the import of Japanese silk and substituted domestically produced synthetic materials for this foreign product. DuPont played a significant role in these inventions, with its slogan: “Better Things for Better Living … Through Chemistry.” In the June 1941 issue of DuPont Magazine, this chemical company declared as follows: “We are manufacturing in the homeland some commodities that were formerly imported––materials that can, if necessary, serve as replacements, such as neoprene for rubber and nylon for silk” (“Men, Materials, Service” 1941). Emphasizing the word “synthetic,” DuPont at that time clearly intended to eliminate foreign natural materials and products from the country; in this regard, DuPont Magazine notes, “Synthetic fibers have conquered another stronghold in this country formerly held exclusively by silk imported mainly from Japan” (“What’s New” 1941). While nylon was used for surgical sutures, fishing leaders, racket strings, stockings, and musical strings around the 1940s, it also became part of military products, such as parachutes, aircraft parts, and wire used in radio equipment (see Albee 1943). The strong and growing sense of nationalism and militarism in the United States became a driving force behind the emergence of the synthetic regime in global history.

In the first half of the 1940s, DuPont played an important part of the United States’ national security program (E. I. du Pont de Nemours and Company 1946). In the March 7, 1946 letter that was addressed to its stockholders, DuPont stated as follows:

World War II was a war of science and a war of industries as well as a clash of armies in the field. In this race of laboratories and production lines, the American chemical industry was called upon to take a leading part. Chemical research and manufacture produced not only elements of ordnance that insured military success, but materials which went into strengthening and husbanding the very economy of the nation itself.

Fulfillment of this responsibility can be attributed to the industry’s preparedness in keeping abreast of scientific advancement in a changing world. Since 1918, American chemistry and affiliated sciences have crossed new frontiers in technological advancement. They have created new chemical products, superior in many cases to imported natural and manufactured materials and have ventured successfully into totally new fields of research and development. The effects of this progress, both in the domestic economy and on military power, have now been demonstrated (E. I. du Pont de Nemours and Company 1946, 4).

During the war, the company cooperated with a variety of governmental agencies ranging from the Air Forces Technical Service to the Bureau of Printing and Engraving. The expansion of the company’s plant facilities in Belle, West Virginia, in Seaford, Delaware, and in Martinsville, Virginia helped increase the production of nylon and other man-made fibers (E. I. du Pont de Nemours and Company 1946, 44) (Figure 2). Table 2 shows that the US mill consumption of synthetic fibers, including nylon 66, Orlon, Acrilan, Dynel, and Dacron, among others, notably increased from 4.4 million pounds in 1940 to 482.9 million pounds in 1956, whereas that of silk decreased from 62.3 million pounds in 1935 to 7.7 million pounds in 1956. The embargo on Japanese silk was announced in August 1941 (E. I. du Pont de Nemours and Company 1946, 42). The loss of the natural fiber silk in the United States accelerated the manufacture of synthetic and other man-made fibers. These political-economic conflicts prepared the ground for the rise of the synthetic regime in global capitalism; in the latter half of the twentieth century, synthetic fibers were mass-produced and widely distributed and consumed across the globe.

Figure 2. DuPont’s nylon plant in Martinsville, Virginia in the 1950s. Source: Hagley ID: 1972341_1280,

DuPont Company Product Information photographs (Accession 1972.341),

Audiovisual Collections and Digital Initiatives Department, Hagley Museum and Library, Wilmington, DE 19807.

|

Table 2. US Mill Consumption of Certain Fibers, 1920–1956. (Millions of pounds). |

|||

|

Year |

Rayon and Acetate |

Synthetic Fibers |

Silk |

|

1920 |

8.7 |

– |

29.2 |

|

1930 |

119.3 |

– |

75.6 |

|

1935 |

259.2 |

– |

62.3 |

|

1940 |

482.1 |

4.4 |

35.8 |

|

1945 |

769.9 |

49.8 |

0.5 |

|

1950 |

1,351.6 |

140.5 |

8.4 |

|

1955 |

1,419.2 |

432.1 |

7.2 |

|

1956 |

1,201.1 |

482.9 |

7.7 |

Source: Airov (1959, 18). Synthetic fibers here include nylon 66, Orlon, Acrilan, Dynel, Dacron,

glass fibers, polyethylene fibers, polystyrene fibers, Saran, and Vicara, among others.

How, then, did the Japanese around 1940 react to DuPont’s nylon? There were many reactions to the invention of nylon in the United States, particularly by the Japanese mass media. As early as January 1939, Japanese newspaper Asahi shinbun carried a short article on US nylon, entitled “Nihon kiito no kyōteki: nairon ito no shōtai” (The Strong Enemy of Japanese Silk: The True Character of Nylon Threads) (1939). This article expressed concern that US nylon would become a strong enemy of the Japanese silk industry in the future and eventually threaten the very existence of Japanese silk. By early 1939, the Ministry of Agriculture and Forestry of Japan obtained samples of DuPont nylon from the United States and analyzed its physical properties. The Japanese already knew what nylon was made from and how it was manufactured and realized that the nylon material was strong and relatively elastic (“Nihon kiito no kyōteki” 1939). The Asahi shinbun article described nylon as jinken (artificial silk) as opposed to kiito (natural silk). On April 5, 1939, Asahi shinbun carried another short article on US nylon, which acknowledged that the news about the invention of nylon gave the Japanese silk industry a great shock (“Nairon” 1939). One of modern industry’s hard-and-fast rules was that “artificial goods expel all natural goods” (“Nairon” 1939).6

There were some collective attempts in wartime Japan to invent synthetic fibers as a substitute for US nylon (e.g., vinylon first developed in 1939 by a Kyoto Imperial University research team led by Sakurada Ichirō). In early 1939, Oda Ryōhei and his research team at Kyoto Imperial University began to study US nylon, and at the same time, Tōyō Rayon (founded in 1926 and currently registered as Tōray Industries) initiated an analytical study of the nylon material. However, such attempts in polymer chemistry––a sub-discipline of chemistry that studies the chemical synthesis, characterization, and physical properties of polymer molecules––were ceased as the war intensified in 1944.7 During the first half of the twentieth century, chemical engineering rapidly developed as an academic discipline in the United States; the number of chemical engineering students in this country increased from 869 in 1910 to 17,392 in 1946 (Ndiaye 2006, 49).

It was right after the end of World War II that, particularly during the Allied Occupation period, the rise of nylon along with other man-made fibers like rayon damaged the Japanese sericulture industry. In fact, the General Headquarters paid close attention to the sericulture industry as something that would help revive Japan’s economy after the war (Hirano and Makita 2017, 28). Silk trade reopened in March 1946. But as Hirano and Makita (2017, 28) explain, there was already little demand for silk in the United States, as nylon took over the position of silk in the garment industry, particularly full-fashioned hosiery manufacturing. In the following year, Japan began to export silk to Britain, India, and Australia, and in 1948 to France, Hong Kong, Switzerland, and Italy; however, Japan could no longer expand its sericulture industry (Hirano and Makita 2017, 29).

As Cold War tensions increased by the late 1940s, US policymakers became concerned about the future of Japan’s economy and its defensive capabilities. Historical events like the victory of the Chinese Communist Party and the beginning of the Korean War led the United States, as a leader of the Cold War anti-Communist coalition, to focus on reconstructing Japan from economic and security perspectives. “Rearmament is … a story of institutional development, of the United States’ desire and, though limited, success in creating a Japan mobilized to participate in the Cold War,” writes Jennifer M. Miller (2011, 86). Japan provided a key supply base for US troops. From June 1950 until July 1954, for example, the United States spent approximately three billion dollars in Japan on war-related services and goods (Dingman 1993, 42). The success of Japan’s economic policies during the latter half of the twentieth century depended much on Japan’s alliance with the United States (see, for example, Beckley et al. 2018; Forsberg 2000; LaFeber 1997; Miller 2012; Schaller 1997; Shimizu 2001). The United States supported Japan’s export-oriented growth, as its dedicated buyer (see Beckley et al. 2018, for more on the United States’ role in making Japan’s economic miracle).8 Looking at post-World War II geopolitics indeed helps explain the broader situation and context in which synthetics developed in Japan; as already mentioned, in 1951 Tōyō Rayon formed a technical tie-up with DuPont. Harvard sociologist David Riesman once wrote a fictitious account of a bombing campaign, called “The Nylon War” (1951), which suggested that in order to vanquish the Soviets and throw socialist society into disarray, the United States drop industrial consumer goods including pairs of nylon hose on them from airplanes, rather than explosives.9

This geopolitical-economic context importantly provided the basis for the invention of the nylon string in the Japanese musical instrument industry. In 1960, Marusan Hashimoto invented koto strings made from nylon, probably for the first time in the world of Japanese traditional music.10 Later, nylon gradually replaced silk as the main material for musical strings, especially for the koto strings and the shamisen’s third (thinnest) string. An Asahi shinbun article entitled “Konnichi no mondai: ito” (Today’s Issue: Strings) (1979) warned that the presence and standardization of nylon strings in Japanese traditional music would cause the marginalization of the tradition of silk string making in the near future. In “Dentōgakki to sen’i: koto, biwa, sangen no ito” (Traditional Musical Instruments and Fibers: The Strings of the Koto, Biwa, and Shamisen) (1994), Ozasa Hiroyuki of the string maker Tobaya mentioned that nylon and Tetoron strings together constituted about 70 percent of the koto strings appearing on the market during the late twentieth century, while silk strings constituted the other 30 percent (Ozasa 1994, 644).11

Koto player of the Ikuta school Andō Masateru’s book Ikuta-ryū no sōkyoku (Koto Music of the Ikuta School) (1986) contains some important reflections on the use of those new synthetic materials for the koto during the post-World War II period. Having been written under the editorial supervision of Japanese musicologist Kikkawa Eishi, this comprehensive book on the koto mainly provides readers with information about the instrument, music theory, koto performance techniques, and the history of koto music.12 Andō (1986, 25) noted that the synthetic fiber used for koto strings was initially nylon; however, Tetoron gradually became standard. These synthetic strings were typically stronger and less expensive than silk strings. They were under higher tension than silk strings; higher tension strings tended to produce louder sounds than lower tension strings. Andō (1986, 25) realized that koto players in the post-World War II period began to prefer higher tension strings and the tones such strings produced, and that they demanded louder sounds. Behind these shifts, gendai hōgaku (contemporary traditional Japanese music) was developed by individuals who were trained in Western music and composed progressive traditional music, which was often in contrast to traditional koto music (Johnson 2003, 210). Western musical idioms including tremolo, chordal accompaniment, and triple meter were employed in such progressive traditional music. Moreover, koto players around that time frequently performed in large concert halls with acoustic devices (Andō 1986, 238). Andō rarely had a problem that synthetic strings snapped during performance, even if he used square-edged picks peculiar to the Ikuta tradition (Andō 1986, 43). However, this was not the case for silk strings.

Even after synthetic materials were introduced to Japanese traditional music culture, there were further attempts to improve their material quality and efficacy in music performance. In the mid-1980s, for instance, the then president of Marusan Hashimoto, Hashimoto Keisuke, collaborated with researchers at the Osaka Prefectural Radiation Research Institute (founded in 1959) to enhance the material quality of nylon musical strings through radiation (Hashimoto 2004, 4). Whereas the nylon string was generally stronger and more durable than the silk string, the tone produced through the synthetic material was considered weaker. Hashimoto’s main concerns about synthetic fibers, such as nylon and Tetoron, were as follows: (1) strings made from synthetic fibers got slightly stretchy; (2) this characteristic would result in an unstable tuning; (3) the tone was relatively weaker; and (4) these strings did not ensure a long enough reverberation time (Hashimoto 2004, 3). Marusan Hashimoto’s nylon shamisen strings developed in collaboration with the Osaka Prefectural Radiation Research Institute, called Ray Tone, are still used among shamisen players these days (Figure 3). In the synthetic regime of the twentieth century, industrial chemicals and related products became vastly distributed across time and space––and cultures.

Figure 3. Marusan Hashimoto’s nylon shamisen strings called “Ray Tone.”

Photo by the author.

In the world of Western art music, besides Albert Augustine’s nylon guitar strings, harp maker Melville A. Clark of Syracuse, New York in the late 1940s invented harp strings by using DuPont nylon. The physical properties of the nylon harp strings were a bit different from those of their predecessors, namely gut strings; the nylon harp strings were generally strong and not affected by humidity (see Kaiser 2010, 54–61). Harpists around that time reported that the nylon harp string was more elastic than the gut string, and it took longer to maintain a constant pitch (“Strings for Harps Are Made of Nylon” 1948). During the 1940s and 1950s, instrument string manufacturer D’Addario also employed the new DuPont material and perfected its own nylon strings; D’Addario thought that nylon was suitable particularly for harp strings and the treble strings of the classical guitar. In this process, D’Addario counted much on artist feedback from French harpist Carlos Salzedo (1885–1961) (see La Gorce 2014). These nylon strings imitated the materiality and functionality of natural strings made from the intestines of animals.

These Japanese and Western cases together show that synthetic strings were basically always modeled after natural strings in terms of sonic qualities as well as physical properties, while, of course, nylon had its own strengths. It appears that the existence of the synthetic presupposes its coexistence with the natural as a model of being; these categories help define each other in cultural and political economies.

This global-historical approach to understanding how modern cultural industry dealt with natural and synthetic materials and materialities across time helps us realize that a series of seemingly unrelated local cultural phenomena and industries––ranging from Western art music/Western musical instrument industries to traditional Japanese music/Japanese musical instrument industries––can relate to each other. Since around the mid-twentieth century, musical instrument industries across the globe tended to substitute elastic, durable synthetic fibers for natural fibers produced by silkworms in making cocoons or others made from the intestines of animals.

Conclusion

This article reveals the power that has brought about the emergence of a set of local phenomena in which instrument manufacturers, ranging from Western musical instrument makers to Japanese musical instrument makers, invented nylon strings in the mid- to late twentieth century. But the invention of synthetics also contributed to the development of the global garment, textile, sporting goods, and military industries, among many others. To understand the broader shift from using natural materials to synthetic ones in consumer cultures across the globe, one may need to look closely at the political-economic conflicts between the United States and Japan, especially during World War II, and postwar geopolitics. Conceptualizing the rise of global capitalism’s synthetic regime helps one become aware that the problem inherent in nylon manufacturing, for example, includes more than just the extraction of natural resources, such as water, coal, petroleum, and air. It further encompasses the capitalist ethos of ceaselessly copying and artificially reproducing the physical properties of the natural (e.g. silk), with the primary objective of maximizing profit. In these processes, capitalism may function as a way of intensifying a kind of speciesism that rationalizes continued exploitative use of certain natural resources.

In the synthetic regime, the development of modern chemistry and chemical engineering in the Global North facilitated the artificial production of the natural, both quantitatively and qualitatively, in the dynamics and politics of global economies. As discussed earlier in this article, over the twentieth century the Global North was the most producer of nylon fibers and, consequently, that of nitrous oxide in the earth’s atmosphere; atmospheric nitrous oxide has contributed to global warming (Thiemens and Trogler 1991). Also, as Larry B. Clayton (1981, 18) notes in Summary of Trade and Tariff Information: Manmade Fibers and Filament Yarns, during 1980, for instance, man-made fiber waste amounted to approximately 22 million pounds, valued at more than five million US dollars.

The notion of “ecologically unequal exchange” (Bunker 1985, 2007; Foster and Holleman 2014; Hornborg 2012; Roberts and Parks 2009) generally describes disproportionate flows of energy and raw materials from the Global South to the Global North. Global trade relations remain unfair and unbalanced since poor nations export their natural resources to manufacturers; Roberts and Parks (2009, 388) recognize “the mounting cry from developing countries that they are owed an ‘ecological debt’ by the North.” World-systems theorists indicate that “the global ‘structure’ of inequality remains a central concern” (Roberts and Parks 2009, 389). My case study can provide another critical view on the issue of the global structure of inequality: corporations from the Global North have accumulated capital by tactically appropriating nature (cf. Moore 2015) as well as by exploiting human and more-than-human labor, while planetary-scale issues such as climate change and biodiversity loss are imposed not only on those richest and most industrialized countries, but also on the Global South. This “nature,” as in the discussions of silk and synthetics, can be something that has significantly affected the course of human society over time, but it has also been largely defined by the development of biotechnology and chemical engineering, among others.

In the synthetic regime, the Global North newly became a collective geological agent. In what Kathryn Yusoff (2013) calls a “geological turn,” humans as geological agents “[take] seriously not just our biological (or biopolitical) life, but our geological (or geopolitical) life, as crucial to modes of subjectification in the Anthropocene” (Yusoff 2013, 780). Capitalism itself functions as a “geosocial machine”; it has increasingly become capable of organizing “modes of capture that capitalize on geopower” (Yusoff 2017, 113). In examining the production of nylon, we can thus identify a form of geopower that is exercised to extract, organize, and synthesize a set of certain natural resources. In this sense, the argument for degrowth (Hornborg 2019) may gain its relevance, so long as the idea of “growth” continues to, in reality, result in both the accumulation of capital and environmental degradation (cf. Hornborg 2016, 74). “The argument for degrowth is necessarily also an argument against capitalism,” writes Alf Hornborg (2019, 2). But it seems to be imperative, at the same time, that we keep creating tales about how we maintain the earth systems in the Anthropocene.13

Acknowledgements

I presented a condensed version of this article in an organized session entitled “Ethnomusicological Approaches to Political Economy and Resource Ecologies” at the Society for Ethnomusicology’s 2020 Virtual Annual Meeting. I would like to thank Eliot Bates, Justin Patch, Tom Wagner, and Anna Morcom for insightful discussions during the session. I want to thank Jim Sykes as well for his encouragement. I also presented this research in the 2021 Summer Institute for East Asian Studies program, organized by the Asian Studies Center at the University of Pittsburgh; I am very thankful to the participants of the program, especially Weihong Bao, Madeline Eschenburg, Calvin Hui, and Kirsten Strayer, for their critical feedback. I am deeply grateful to Dick Smethurst for his generous and insightful feedback on the manuscript. I would like to extend my sincere thanks to the anonymous reviewer and to editor Mark Selden for their helpful comments. This research was supported by the University of Pittsburgh Japan Iron & Steel Federation endowment.

References

Airov, Joseph. 1959. The Location of the Synthetic-Fiber Industry: A Case Study in Regional Analysis. Cambridge, MA: The MIT Press.

Albee, George. 1943. “Nylon Goes Aloft.” DuPont Magazine 37, no. 3: 2–5.

Andō, Masateru. 1986. Ikuta-ryū no sōkyoku [Koto Music of the Ikuta School]. Tokyo: Kōdansha.

Beckley, Michael, Yusaku Horiuchi, and Jennifer M. Miller. 2018. “America’s Role in the Making of Japan’s Economic Miracle.” Journal of East Asian Studies 18: 1–21.

Beldo, Les. 2017. “Metabolic Labor: Broiler Chickens and the Exploitation of Vitality.” Environmental Humanities 9, no. 1: 108–28.

Bunker, Stephen G. 1985. Underdeveloping the Amazon: Extraction, Unequal Exchange, and the Failure of the Modern State. Chicago: The University of Chicago Press.

Bunker, Stephen G. 2007. “Natural Values and the Physical Inevitability of Uneven Development Under Capitalism.” In Rethinking Environmental History: World-System History and Global Environmental Change. Ed. Alf Hornborg, J. R. McNeill, and Joan Martinez-Alier, 239–58. Lanham, MD: AltaMira Press.

Clayton, Larry B. 1981. Summary of Trade and Tariff Information: Manmade Fibers and Filament Yarns. Washington, DC: US International Trade Commission.

Darlington, Brooks. 1934. “The Story of a Yarn.” DuPont Magazine 28, nos. 7–8: 10–15, 24.

Destler, I. M., Haruhiro Fukui, and Hideo Sato. 1979. The Textile Wrangle: Conflict in Japanese-American Relations, 1969–1971. Ithaca, NY: Cornell University Press.

Dingman, Roger. 1993. “The Dagger and the Gift: The Impact of the Korean War on Japan.” The Journal of American-East Asian Relations 2, no. 1: 29–55.

E. I. du Pont de Nemours and Company. 1946. The du Pont Company’s Part in the National Security Program, 1940–1945. Wilmington, DE: E. I. du Pont de Nemours and Company.

Forsberg, Aaron. 2000. America and the Japanese Miracle: The Cold War Context of Japan’s Postwar Economic Revival, 1950–1960. Chapel Hill, NC: University of North Carolina Press.

Foster, John Bellamy, and Hannah Holleman. 2014. “The Theory of Unequal Ecological Exchange: A Marx-Odum Dialectic.” Journal of Peasant Studies 41, no. 2: 199–233.

Foucault, Michel. 1990. The History of Sexuality, Volume 1: An Introduction. Trans. Robert Hurley. New York: Vintage Books.

Foucault, Michel. 2003. Society Must Be Defended: Lectures at the Collège de France, 1975–1976. Ed. Mauro Bertani and Alessandro Fontana. Trans. David Macey. New York: Picador.

Furukawa, Yasu. 2007. “Karōzaasu to nairon: densetsu saikō” [Carothers and Nylon: Reconsidering the Legend]. Kagaku to kyōiku 55, no. 6: 274–77.

Grover, Elliot B., and Dame S. Hamby. 1951. Textile Processing of Synthetics: Continuous Filament. Raleigh, NC: The Technical Press.

Handley, Susannah. 1999. Nylon: The Story of a Fashion Revolution. Baltimore, MD: Johns Hopkins University Press.

Harris, Milton, ed., 1954. Handbook of Textile Fibers. Washington, DC: Harris Research Laboratories.

Hashimoto, Keisuke. 2004. “Shamisen ito to hōshasen no kakawari” [The Relationship Between Shamisen Strings and Radiation]. ONSA News 14, nos. 2–3: 1–4. (accessed May 9, 2020).

Hirano, Kyōhei, and Hisami Makita. 2017. “‘Nairon no shōgeki’ to Nihon no sanshigyō no suitai: Amerika shijō no hen’yō to GHQ niyoru dezain ikusei” [Nylon’s Impact and the Decline of the Japanese Silk Industry: Changes in the American Market and GHQ’s Development Policy of Textile Design]. Gijutsu to bunmei 21, no. 2: 21–38.

Hornborg, Alf. 2012. “Accumulation: Land as a Medium of Domination.” In Ecology and Power: Struggles over Land and Material Resources in the Past, Present and Future. Ed. Alf Hornborg, Brett Clark, and Kenneth Hermele, 13–22. Abingdon, Oxon: Routledge.

Hornborg, Alf. 2016. “Post-Capitalist Ecologies: Energy, ‘Value’ and Fetishism in the Anthropocene.” Capitalism Nature Socialism 27, no. 4: 61–76.

Hornborg, Alf. 2019. Nature, Society, and Justice in the Anthropocene: Unraveling the Money-Energy-Technology Complex. Cambridge: Cambridge University Press.

Inoue, Naoyuki. 1997. “Karozaasu no nairon hatsumei ga Nihon shakai oyobi kōbunshi kagaku no hatten ni ataeta eikyō” [The Influences of Carothers’s Invention of Nylon on Japanese Society and the Development of Polymer Chemistry]. PhD diss., Osaka Prefecture University.

Johnson, Henry. 2003. “Traditions Old and New: Continuity, Change, and Innovation in Japanese Koto-Related Zithers.” Journal of the American Musical Instrument Society 29: 181–229.

Johnson, Henry. 2004. The Koto: A Traditional Instrument in Contemporary Japan. Amsterdam: Hotei Publishing.

Kaiser, Linda Pembroke. 2010. Pulling Strings: The Legacy of Melville A. Clark. Syracuse, New York: Syracuse University Press.

“Konnichi no mondai: ito” [Today’s Issue: Strings]. 1979. Asahi shinbun, April 23, evening edition, 2.

La Gorce, Tammy. 2014. “Before the Music Come the Machines: The D’Addario Factory Makes Millions of Strings for Guitars, Violins and Other Instruments.” The New York Times, December 14, LI11.

LaFeber, Walter. 1997. The Clash: U.S.–Japanese Relations throughout History. New York: WW Norton.

Marusan Hashimoto. 2020. “Rekishi” [History]. (accessed April 21, 2020).

“Men, Materials, Service.” 1941. DuPont Magazine 35, no. 6: 16.

Miller, Jennifer M. 2011. “The Struggle to Rearm Japan: Negotiating the Cold War State in US-Japanese Relations.” Journal of Contemporary History 46, no. 1: 82–108.

Miller, Jennifer M. 2012. “Building a New Kind of Alliance: The United States, Japan, and the Cold War, 1950–1961.” PhD diss., University of Wisconsin-Madison.

Moncrieff, R. W. 1963. Man-Made Fibres: Formerly Artificial Fibres. 4th ed. New York: Wiley.

Moore, Jason W. 2015. Capitalism in the Web of Life: Ecology and the Accumulation of Capital. New York: Verso.

Morris-Suzuki, Tessa. 1992. “Sericulture and the Origins of Japanese Industrialization.” Technology and Culture 33, no. 1: 101–21.

“Nairon” [Nylon]. 1939. Asahi shinbun, April 5, morning edition, 3.

Ndiaye, Pap A. 2006. Nylon and Bombs: DuPont and the March of Modern America. Baltimore: Johns Hopkins University Press.

“Nihon kiito no kyōteki: nairon ito no shōtai” [The Strong Enemy of Japanese Silk: The True Character of Nylon Threads]. 1939. Asahi shinbun, January 28, morning edition, 4.

Onaga, Lisa A. 2010. “Toyama Kametaro and Vernon Kellogg: Silkworm Inheritance Experiments in Japan, Siam, and the United States, 1900–1912.” Journal of the History of Biology 43: 215–64.

Onaga, Lisa A. 2013. “Bombyx and Bugs in Meiji Japan: Toward a Multispecies History?” The Scholar & Feminist Online 11, no. 3. (accessed January 25, 2021).

Ozasa, Hiroyuki. 1994. “Dentōgakki to sen’i: koto, biwa, sangen no ito” [Traditional Musical Instruments and Fibers: The Strings of the Koto, Biwa, and Shamisen]. Sen’i gakkaishi 50, no. 12: 642–44.

Parsons, L. E., and Stearns, John K. 1951. Textile Fibers. Scranton, PA: International Textbook Company.

Rabinow, Paul, and Nikolas Rose. 2006. “Biopower Today.” BioSocieties 1: 195–217.

Riesman, David. 1993. Abundance for What? New Brunswick, NJ: Transaction Publishers.

Roberts, J. Timmons, and Bradley C. Parks. 2009. “Ecologically Unequal Exchange, Ecological Debt, and Climate Justice: The History and Implications of Three Related Ideas for a New Social Movement.” International Journal of Comparative Sociology 50, nos. 3–4: 385–409.

Rosato, Donald V. 2005. Plastics China: Technologies, Markets and Growth Strategies to 2008. Oxford: Elsevier.

Sangyō Gijutsu Kenkyūjo [The Institute of Sericulture], 2010. Yōsan [The sericulture]. Inashiki,

Ibaraki: Sangyō Gijutsu Kenkyūjo. (accessed March 11, 2020).

Schaller, Michael. 1997. Altered States: The United States and Japan since the Occupation. New York: Oxford University Press.

Sherman, Joseph V., and Signe L. Sherman. 1946. The New Fibers. New York: D. Van Nostrand Company.

Shimizu, Sayuri. 2001. Creating People of Plenty: The United States and Japan’s Economic Alternatives, 1950–1960. Kent, OH: The Kent State University Press.

Smethurst, Richard J. 1986. Agricultural Development and Tenancy Disputes in Japan, 1870–1940. Princeton: Princeton University Press.

Smethurst, Richard J. 2020. “Planning for War: Elite Staff Officers in the Imperial Japanese Army and the Road to World War II.” The Asia-Pacific Journal: Japan Focus 18, no. 21, November 1. (accessed June 12, 2021).

“Strings for Harps Are Made of Nylon: Called Better Than Gut for All Plucking Instruments but Not for Those That Are Bowed.” 1948. The New York Times, January 21, 28.

Takizawa, Hideki. 1979. Mayu to kiito no kindaishi [The Modern History of Cocoons and Silk]. Tokyo: Kyōikusha.

Thiemens, Mark H., and William C. Trogler. 1991. “Nylon Production: An Unknown Source of Atmospheric Nitrous Oxide.” Science 251, no. 4996: 932–34.

“Tōyō Reeyon to Dhu Pon de teikei” [The Tie-up between Tōyō Rayon and DuPont]. 1951. Asahi shinbun, April 5, morning edition, 2.

Tsurumi, E. Patricia. 1990. Factory Girls: Women in the Thread Mills of Meiji Japan. Princeton: Princeton University Press.

Uchida, Kaneo. 1994. “Senzenki Nihon no kiito kokunai shijō: kiito kokunai shōhiryō no suikei oyobi chōki jukyū no kōsatsu” [The Domestic Market of Raw Silk in Prewar Japan: An Estimate and Quantitative Analysis of Silk Consumption]. Keieishi gaku 29, no. 4: 26–57.

United States Tariff Commission. 1941. United States Imports from Japan and Their Relation to the Defense Program and to the Economy of the Country. Washington, DC: United States Tariff Commission.

“Virtuoso String Performers.” 1982. DuPont Magazine 76, no. 2: 6–7.

“What’s New.” 1941. DuPont Magazine 35, no. 6: 17.

Yamada, Keisuke. 2017. “Shamisen Skin on the Verge of Extinction: Musical Sustainability and Non-Scalability of Cultural Loss.” Ethnomusicology Forum 26, no. 3: 373–96.

Yamada, Keisuke. 2020a. “The Political Economy of Nonlife: Biopower, Ontosecurity, and the Shamisen Skin Trade in Japan.” In The Oxford Handbook of Economic Ethnomusicology. Ed. Anna Morcom and Timothy D. Taylor. New York: Oxford University Press. Advance online publication.

Yamada, Keisuke. 2020b. “On More-Than-Human Labor: Revisiting Japan’s Ecological Modernity and the Politics and Ethics of Interspecies Entanglements.” Japan Forum. Advance online publication.

Yamada, Keisuke. 2020c. “Ecologies of Instrumentality: The Politics and Practice of Sustainable Shamisen Making.” PhD diss., University of Pennsylvania.

“Yōsanka no tachiba” [Sericulturists’ Situation]. 1939. Asahi shinbun, April 8, morning edition, 3.

Yusoff, Kathryn. 2013. “Geologic Life: Prehistory, Climate, Futures in the Anthropocene.” Environment and Planning D: Society and Space 31: 779–95.

Yusoff, Kathryn. 2017. “Geosocial Strata.” Theory, Culture & Society 34, nos. 2–3: 105–27.

Notes

When Japanese names appear in the main text, the surname comes before the given name, per standard usage in Japan, except for those of authors of scholarly articles or books originally written in English. All translations from Japanese are my own, with the exception of those already available in English.

For a comprehensive list of names, types, and manufacturers of man-made fibers that existed in the mid-twentieth century, see Harris (1954, 43–48).

Silk-reeling was gendered labor. In early modern Japan, sericulture was part of the life of the patriarchal farm family, and the women of each household had responsibility for taking care of silkworms. See Morris-Suzuki (1992, 112–13).

During the 1970s, Michel Foucault (1990, 2003) introduced the notion of biopolitics and biopower to describe a form of power exercised upon living populations of certain species. For a recent interpretation of Foucauldian biopower, see Rabinow and Rose (2006).

Richard J. Smethurst points out Japan’s economic weakness around that time; he writes, “In 1930, Japan ranked last in GDP of the seven major World War II powers, US, USSR, Great Britain, France, Germany, Italy and Japan in that order” (Smethurst 2020).

For more on the impact of US nylon on the development of polymer chemistry in twentieth-century Japan, see Inoue (1997).

There is literature on political-economic conflicts over trade in textile products between the United States and Japan during the late twentieth century. See, for example, Destler et al. (1979).

For the entire piece, see Riesman (1993, 67–79). Note that “The Nylon War” was originally published in Common Cause 4, no. 6: 379–85.

Tetoron is a type of polyester invented by Japanese chemical companies Tōray Industries and Teijin in the late 1950s.

For English-language scholarship on the koto, see especially the work of Henry Johnson (2003, 2004).

My critical study of musical instrument industries aims to encourage readers to be conscious of the darker side of the historical development and progressive nature of music industries on a global scale, which undoubtedly included a huge amount of sacrifice, extraction, and exploitation of the lives of nonhuman species and other natural resources over centuries. But it also aims to cover people’s attempts today to contribute to environmental conservation as well as cultural sustainability. See Yamada (2017, 2020a, 2020b, 2020c).